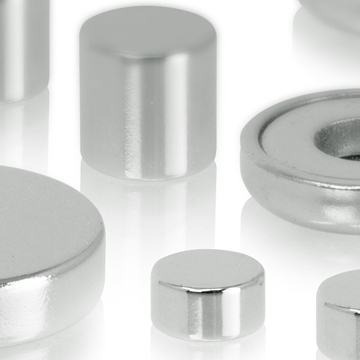

Five Factors That Will Reduce The Performance of Your Magnet

Every one of our magnets has a ‘pull’ rating measured in kilograms and this relates to how much force is required to pull the magnet from a steel plate.

Five Factors That Will Reduce The Performance of Your Magnet Read More »